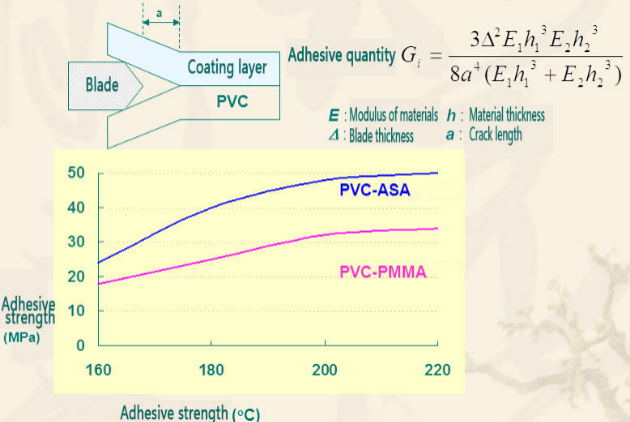

ASA-PVC co-extruded wood is extruded from two extruders, PVC plastic wood substrate and ASA co-extruded coating material, and then through the co-extrusion compound die, the ASA coating layer adheres when extruded with the substrate.

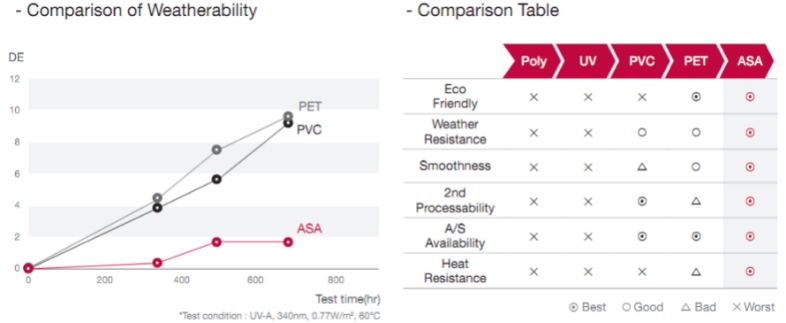

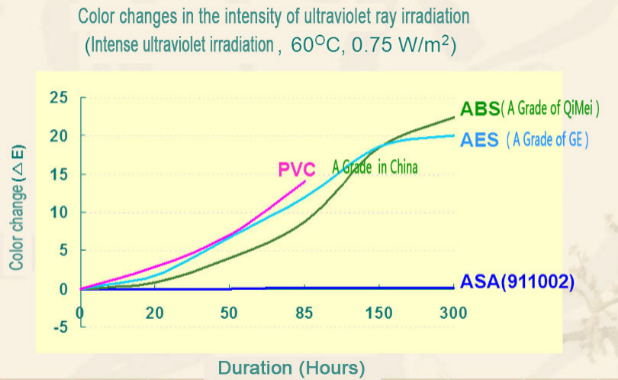

On the surface of the substrate, achieve the purpose of coating the substrate. Co-extrusion coating properties are also different due to the different materials used in the coating. Currently, the co-extruded coating materials mainly include PMMA, PVC and ASA.

With the global depletion of forest resources and the increasing awareness of national environmental protection, the wood-plastic industry has developed well, and ASA-PVC co-extruded wood has also been widely used in gardens, transportation, construction, home improvement, cars and boat interiors.

| ASA property parameter table | |||||

| Property item | Test condition | Test method | ASA | Unit | |

| Physical properties | Specific gravity | ASTM D792 | 1.06 | ||

| Water absorption rate | ASTM D570 | 0.03 | % | ||

| Mould contraction rate | 3.2mm | ASTM D955 | 4-6 | E-3 | |

| Melt idex | ASTM D1238 | / | g/10min | ||

| Mechanical properties | Izod notched impact strength | ASTM D256 | 533 | J/m | |

| Tensile strength (yield point) | ASTM D638 | 39 | Mpa | ||

| Tensile rate (rupture point) | ASTM D638 | 30 | % | ||

| Flexural yield strength | ASTM D790 | 54 | Mpa | ||

| Flexural modulus | ASTM D790 | 1650 | Mpa | ||

| Hardness | Rockwell | ASTM D785 | / | R | |

| Thermal properties | Heat deflection temperature HDT/A | 0.45Mpa | ASTM D648 | 96 | °C |

| Heat deflection temperature HDT/A | 1.8Mpa | ASTM D648 | 82 | °C | |

| Vicat softening point | ASTM D1525 | / | °C | ||

| UL Long-term use temperature | UL746B | 50 | °C | ||

| Flame retardant | 3.0mm | UL94 | HB | ||

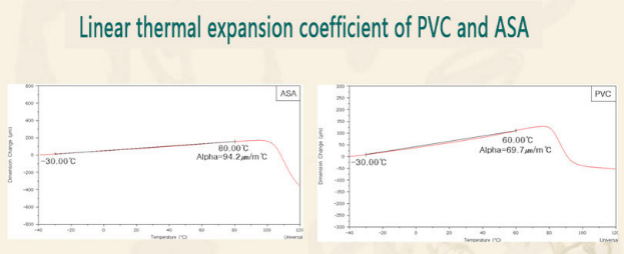

| Linear Expansibility | fluidity | E831 | / | 1/°C | |

| Electrical properties | Dissipation factor | 60Hz | ASTM D150 | / | |

| Permittivity | 60Hz | ASTM D150 | / | ||

| Dielectric strength | ASTM D149 | / | kv/mm | ||

| (Ohm-cm) Surface residtivity | ASTM D257 | / | Ω-cm | ||

| (Ohm-cm) Volume residtivity | ASTM D257 | 1.00E+15 | Ω-cm | ||

Leave your needs, we will contact you in the first time!